product description:

The butterfly plate of the wafer lug butterfly valve is installed in the diameter direction of the pipe. In the cylindrical channel of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis with a rotation angle between 0° and 90°. When rotated to 90°, the valve is fully open.

The wafer butterfly valve uses studs to connect the valve between two pipe flanges. It has a simple structure, small size and light weight, and consists of only a few parts. Moreover, it only needs to be rotated 90° to quickly open and close, which is simple to operate. At the same time, the valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the thickness of the butterfly plate is the only resistance when the medium flows through the valve body. Therefore, the pressure drop generated by the valve is very small, so it has good flow control characteristics. Butterfly valves have two sealing types: elastic seal and metal seal. For elastic sealing valves, the sealing ring can be embedded in the valve body or attached to the periphery of the butterfly plate.

Application scope:

Butterfly valves are not only widely used in general industries such as petroleum, gas, chemical industry, and water treatment, but are also used in the cooling water system of thermal power stations.

Used in gas pipelines in the sulfuric acid industry: furnace blower entrances and exits, relay fan entrances and exits, electric defogger series and connecting valves, S02 main blower entrances and exits, converter adjustment, preheater entrances and exits, etc. to adjust and cut off the gas volume.

It is used in the sulfur burning, conversion, and dry suction sections of the sulfur acid production system. It is the preferred brand of valves for sulfur acid production equipment. It is considered by the majority of users to have good sealing performance, light operation, secondary corrosion, high temperature resistance, and easy operation. Flexible, safe and reliable butterfly valves have been widely promoted and used.

Wafer butterfly valves are also widely used in: SO2, steam, air, coal gas, ammonia, CO2 gas, oil, water, brine, alkali, seawater, nitric acid, hydrochloric acid in chemical, petrochemical, smelting, pharmaceutical, food and other industries. It is used as a regulating and intercepting device on pipelines for media such as sulfuric acid and phosphoric acid.

Structural features:

① The unique three-way eccentric design enables friction-free transmission between the sealing surfaces, extending the service life of the valve.

②Elastic sealing is generated by torque.

③The ingenious wedge-shaped design enables the valve to have an automatic sealing function that becomes tighter and tighter as it is closed, with compensation and zero leakage between the sealing surfaces.

④Small size, light weight, light operation, easy to install.

⑤ Pneumatic and electric devices can be configured according to user requirements to meet the needs of remote control and program control.

⑥The material of the replacement parts can be applied to various media, and the lining can be anti-corrosion (lined with F46, GXPP, PO, etc.).

Performance Comparison of Wafer Butterfly Valve and Gate Valve Compared with ordinary butterfly valves and gate valves with the same nominal pressure and nominal diameter, the sealing performance of the gate valve is better than that of the butterfly valve.

Gate valves are large and take up a lot of space.

Butterfly valves are small in size and take up little space.

When making specific selections, the temperature of the medium, the sealing and packing of the valve should also be considered.

The specification stipulates that butterfly valves should be used for nominal diameters greater than 50.

The high-performance manual wafer butterfly valve adopts a double eccentric and a special inclined cone elliptical sealing structure. It solves the problem that the sealing surface of the traditional eccentric butterfly valve is still in sliding contact friction at the moment of opening and closing 0°~10°, and achieves the effect that the sealing surface of the butterfly plate is separated at the moment of opening and the contact is closed when the sealing is closed, thereby extending the service life and maximizing the sealing performance. Good purpose.

Standard specifications:

Design and manufacturing standards: GB/T 12238-2008, ANSI B16.34, API609, MSS SP-68, JIS B2032, JIS B2064

Structural length standards: GB/T 12221-2005, API609, JIS B2002

Connection flange standards: GB/T 9113, JB79, SH3406, HG20592, ASME B16.5, ASME B16.47, API605, JIS B2212

Pressure temperature grade: GB/T 12224-2005

Test and inspection standards: GB/T 13927-2008, API598, JIS B2003

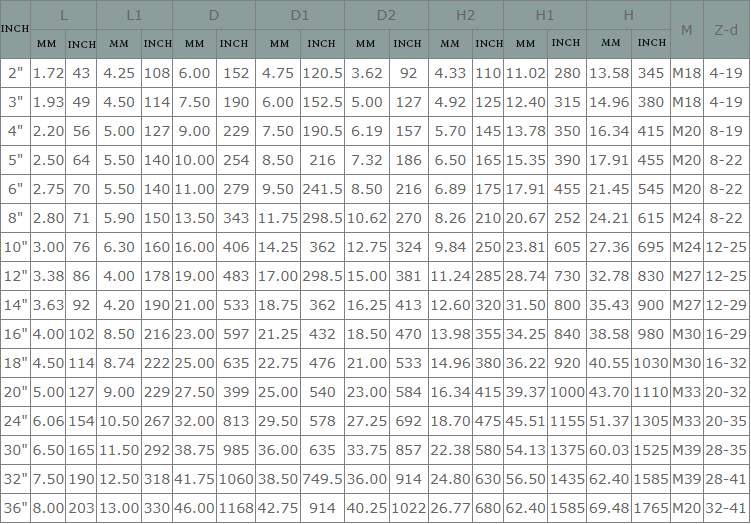

Main dimensions and weight: