1. Product Overview

Based on the introduction of advanced foreign technology, our factory adopts precision J-shaped elastic sealing rings and three-eccentric multi-layered metal hard sealing structures. It is widely used in metallurgy, electric power, petrochemical industry, and water supply and drainage where the medium temperature is ≤425°C. It is used to regulate flow and load-break fluids on industrial pipelines such as municipal construction and municipal construction. The valve adopts a triple eccentric structure. The valve seat and disc sealing surfaces are made of different hardness and stainless steel. It has good corrosion resistance and long service life. This valve has a two-way sealing function. The product complies with the national GB/T13927-92 valve pressure Test Standard.

2. Characteristics

1. This valve adopts a three-eccentric sealing structure, with almost no wear on the valve seat and butterfly plate, and has a sealing function that becomes tighter as you look.

2. The sealing ring is made of stainless steel, which has the dual advantages of metal hard sealing and elastic sealing. It has excellent sealing performance no matter under low or high temperature conditions, and has the characteristics of corrosion resistance and long service life.

3. The sealing surface of the disc is made of cobalt-based hard alloy surfacing. The sealing surface is wear-resistant and has a long service life.

4. The large-sized butterfly plate adopts a quilted frame structure, which has high strength, large flow area and small flow resistance.

5. This valve has a two-way sealing function. It is not restricted by the flow direction of the medium or affected by the spatial position during installation. It can be installed in any direction.

6. The driving device can be installed in multiple positions (rotated 90° or 180°), making it convenient for users to use.

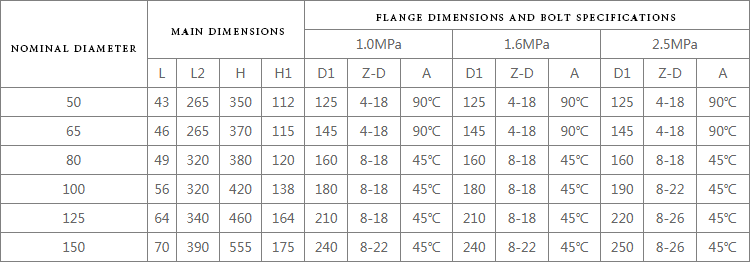

Main external connection dimensions of D73H-10/16/25/wafer-type hard-seal butterfly valve (unit: mm)