How to choose the right flange?

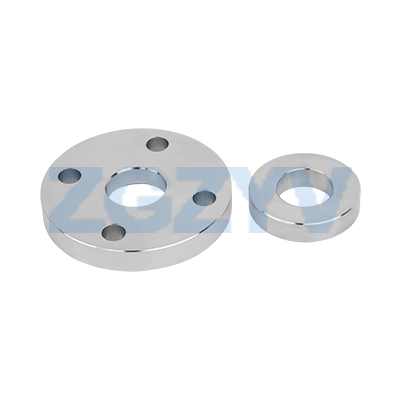

Flanges are connecting parts in industrial pipes, valves and equipment. Most of them are in the shape of perforated discs, which are sealed and tightened by bolts.

Flanges can be assembled and disassembled flexibly, while ensuring the safe operation of the system!

To select a suitable flange, you should refer to the following:

1. Matching standards

Select standard models such as national standard (GB), American standard (ANSI), Japanese standard (JIS) according to project requirements.

2. Material selection

1. Carbon steel: economical and general (such as Q235)

2. Stainless steel: corrosion-resistant (such as 304, 316L)

3. Alloy steel: resistant to high temperature and high pressure (such as 15CrMo)

3. Pressure level

Such as PN16 (16bar), Class150 (American standard 150psi), which needs to be higher than the maximum working pressure of the system.

4. Sealing surface type

1. Flat surface (FF): low pressure and normal temperature

2. Convex surface (RF): general type

3. Concave and convex surface (MFM), tongue and groove surface (TG): high pressure and severe working conditions