What pitfalls should be avoided when choosing power station valves?

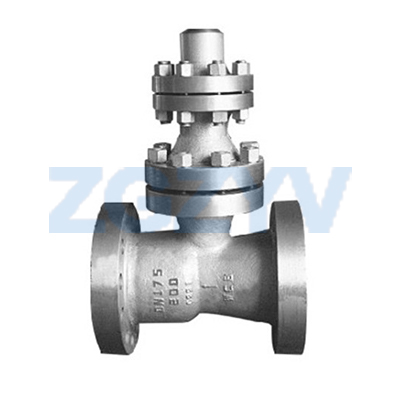

Power station valves are like the “traffic police” of the power system, which are responsible for controlling the flow direction, speed and pressure of water, steam, oil and other media in the pipeline to ensure the safety and stability of the power generation process.

There are three points to note when selecting power station valves:

1. Avoid overkill

Low-pressure circulating water systems do not need to use high-cost alloy steel valves, and 304 stainless steel butterfly valves can meet the needs.

2. Be wary of media compatibility

Ordinary stop valves are prohibited for media containing solid particles (such as mortar), and knife gate valves or V-type ball valves should be selected.

3. Verify the sealing level

Nuclear power plant Class I valves must meet the ANSI B16.104 Class V sealing standard, and ordinary power plants can meet Class IV.

The selection of power station valves must focus on the three cores of medium characteristics, functional requirements, and material adaptation. Standardized products should be given priority in combination with operating parameters, while taking into account operation and maintenance costs.